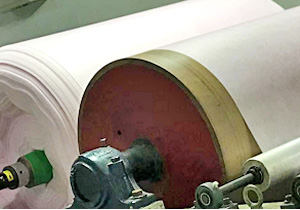

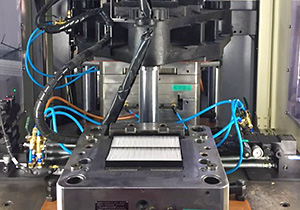

Manufacturing Method & Equipment

The company has a complete production line from the production of raw material filter materials to the processing of finished products for customer requirements. It has the characteristics of stable product quality and quick response.